Description

- 4″ (100 mm) diameter

- Use in horizontal or vertical position

- Worm ratio is 72 to 1

- 10 second rotational accuracy

- 2 Morse taper center hole

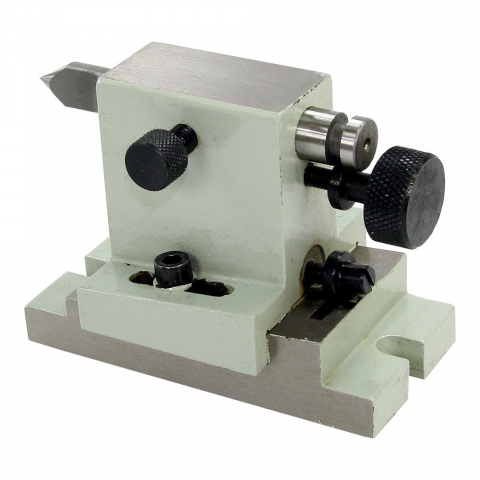

This 4″ horizontal/vertical rotary table is perfect for indexing, circular cutting, angle setting, boring, and spot facing operations on a milling machine. This rotary table is made of precision machined cast iron and has a 2 Morse taper center hole. The table is graduated with a 360 degree scale. The rotary table is furnished with lock down clamps.

This rotary table comes with an adapter to mount a 3″ lathe chuck. It works with both 3- and 4-jaw chucks.

The model 1810 4″ Precision Rotary Table is 2.87″ high when horizontal, and the centerline is 2.68″ above the table when in the vertical position. The body of the table is 5″ (crank handle to back) by 5.5″ (mounting slot to mounting slot).

The worm ratio is 72 to 1.

Flatness of clamping surface: 0.0008″.

Parallelism of clamping surface to base: 0.0008″.

Squareness of clamping surface to angle face: 0.0012″.

Squareness of clamping surface to center slot: 0.0012″.

Concentricity of center bore: 0.0008″ TIP.

| Ratio | 72:1 |

| Table Diameter | 3.9″ (100 mm) |

| Height (mounted horizontal) | 2.9″ (73 mm) |

| Body Length | 5.5″ (140 mm) |

| Body Width | 5.0″ (126 mm) |

| Center Hole Taper | 2 Morse Taper |

| Center Height (mounted vertically) | 2.68″ (68.0 mm) |

| T-slot Width | 0.31″ (8.0 mm) |

| Minimum Vernier Reading | 10″ |

| Flatness of table surface (concave) | 0.0008″ (0.020 mm) |

| Parallelism of table surface to base | 0.0008″ (0.020 mm) |

| Squareness of table surface to base | 0.0012″ (0.030 mm) |

| Runout of table surface | 0.0006″ (0.015 mm) |

| Runout of center taper | 0.0008″ (0.020 mm) |

| Squareness of table surface to angle face slot | 0.0012″ (0.030 mm) |

| Center hole parallel with the angle face | 0.0008″ (0.020 mm) |

| Maximum spacing error | 70″ |

Reviews

There are no reviews yet.